At present, in the general led lighting market, there are non-isolated and isolated driving power sources. The so-called isolated power supply means that the input mains (220V AC in China) is electrically isolated from the output, and the non-isolated power supply is not isolated. In the LED luminaire, the isolated power-driven LED lamp bead is separated from the 220V mains, and the non-isolated power-driven lamp bead is connected to the mains. Performance, the advantages of isolated power supply is: no threat to the human body, wide voltage performance is very good, non-isolated is now very mature, the voltage range is slightly worse than the isolation, the voltage range is between 110V-300V, and The isolated power supply can achieve 60-300V. The high and low currents are very uniform. The isolated drive is safe but less efficient, and the non-isolated drive is more efficient. The isolated or non-isolated drive should be selected according to the actual requirements. From the constant current accuracy: the isolation type can be achieved within ±5%, and the non-isolated type can also be done. Non-isolated circuits are very sensitive to surges and have poor rejection. Lightning surge, this voltage is instantaneous high voltage, up to several thousand volts, the time is very short, the energy is very strong, this voltage enters the power supply, for the non-isolated BUCK circuit, it will instantaneously convey the output, destroy the constant current detection ring, or Further destroying the chip, causing 300v straight through, and burning the entire tube, the strategy is to add lightning protection and surge devices to the input. In fact, it refers to the non-isolated power supply. When the shipment is in bulk, the repair rate is higher than that of the isolated LED driver, mostly because it is damaged. The probability of isolated power supply bursting is much smaller, and non-isolated is generally around 2% to 3%. LED drive power, what is non-isolated? What is isolation? Can the power supply be certified? What is the difference between the power supply of A manufacturer and B manufacturer? Our goal is to make it possible for groups other than engineers to figure out what LED power is. OREMA QTF series AGM start-stop batteries are at the forefront of lead-carbon technology, tailored for vehicles with start/stop and mild hybrid systems. Ideal for caravans, boats, motorhomes, and more, these batteries showcase exceptional charge acceptance and cold starting capabilities. Experience the difference with OREMA's advanced lead alloy formula, specifically designed for today's demanding automotive applications. car start-stop battery,Start-stop battery,AGM Start-stop batteries,AGM battery for car,12V AGM car batteries OREMA POWER CO., LTD. , https://www.oremapower.com

Key Features of OREMA 12V AGM car batteries:

Enhanced Durability: Crafted with reinforced design, the battery casing and cover are made of high-strength, heat-resistant PP engineering plastic, ensuring longevity and reliability under various conditions.

Innovative Construction: Equipped with imported pocket-type PE separators, our batteries effectively prevent short circuits due to active material shedding, resulting in low internal resistance and high current discharge.

Advanced Safety Features: Special anti-acid explosion-proof patches are employed to isolate potential sparks, making our batteries safer for everyday use.

Patented Technology: The patented deep cycle positive paste and negative lead carbon technology significantly extends the battery's cycle life.

Efficient Design: Unique labyrinthine cap design allows for smooth electrolyte recirculation, minimizing water wastage and prolonging battery life.

Cutting-edge TTP Welding: Advanced TTP welding technology ensures minimal internal resistance during connections.

Special Valve Design: Prevents corrosion, enhancing the battery's durability.

High Assembly Pressure: This design feature significantly extends the battery's lifespan.

Wide Temperature Range: Our batteries are functional in temperatures ranging from -30°C (-22°F) to 70°C (158°F), accommodating diverse environmental conditions.

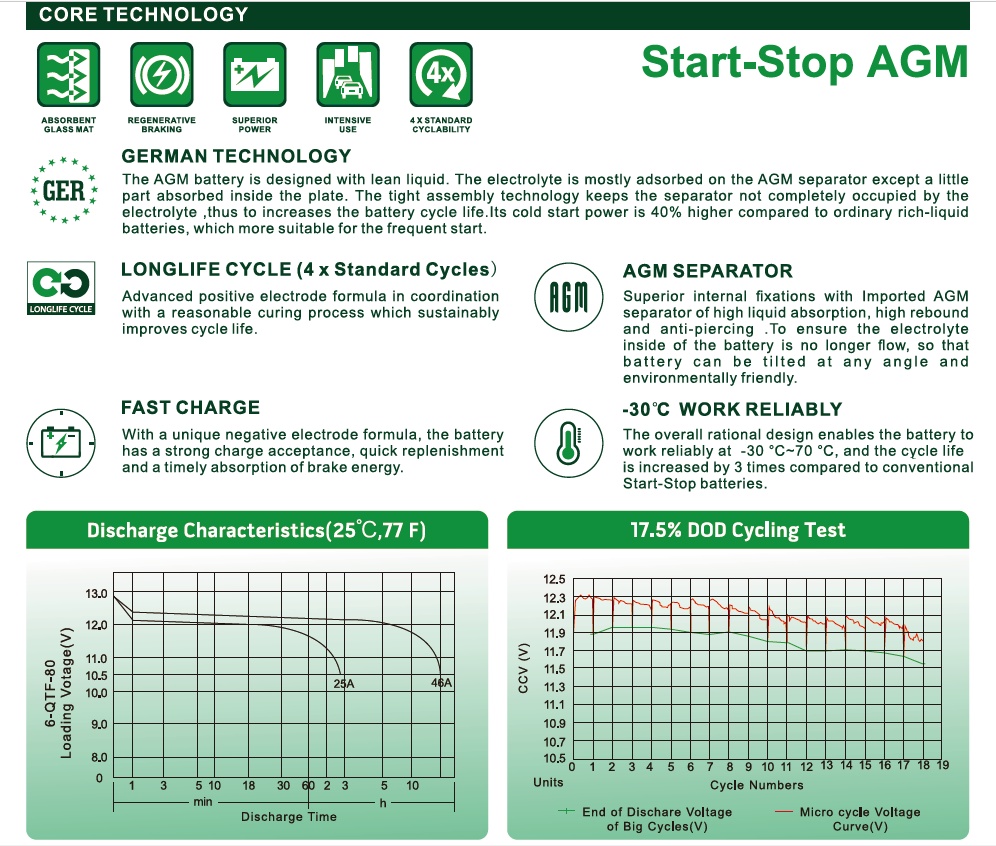

OREMA AGM car start-stop battery core technology:

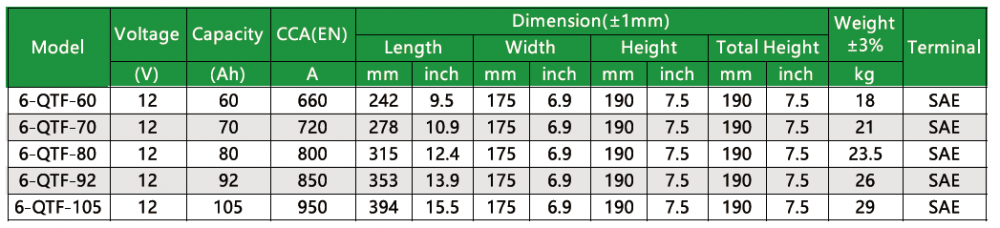

Specifications of OREMA QTF Series AGM Start-stop batteries:

Why choose OREMA as AGM start-stop battery provider?

The upgraded lead-carbon battery technology significantly improves battery life; By adding new active substances to the plate, the charging efficiency is significantly improved; At the same time, the low water loss ensures the long-lasting stability of the battery at high temperatures.

OREMA QTF series AGM automotive batteries introduce innovative technology, showing excellent instantaneous high current release performance, and its continuous casting grid technology enhances the corrosion resistance of the grid; By improving the mechanical strength of the grid, the anti-shock performance of the battery is improved.

The OREMA QTF Series AGM Automotive Battery is known for its powerful starting power, low water loss and long service life, and is specially built for vehicles requiring basic electric support. While maintaining superior performance, it provides a higher price/performance ratio. OREMA QTF Series AGM automotive batteries are designed to simplify life and add value to your car by providing more affordable and responsive battery solutions from the consumer's perspective.

Choose OREMA car batteries, which are prized for their long-lasting performance. Quality products can withstand the test of time and user inspection.